TECHNICAL ASSISTANCE

Being at the same time on the field, in the workshop or in the laboratory to solve technical problems and/or to develop new product lines requests expensive equipments, a bunch of time and a maximum of availability from a technical person !

At FOXMET S.A., we understand your problems and we try our outmost to help you to improve the cutting performances of your sawing tools.

Our technical assistance schema involves:

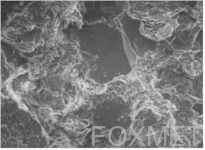

| SEM Pictures |  Arcika Roja/Verde |  Bluestone |

|---|

| Chemical Composition | Silicon (Si) | 67 % | 71 % |

|---|---|---|---|

| Aluminium (Al) | 14 % | 13 % | |

| Iron (Fe) | 8 % | 9 % | |

| Potassium (K) | 8 % | 6 % | |

| Titanium (Ti) | – | 1 % | |

| Calcium (Ca) | 3 % | – |

| Hardness | – | 46 Shore D |

|---|

| Structure | Not homogenous Contains big cristals | Not homogenous Contains few big cristals |

|---|

| Abrasivity | High | Medium to High |

|---|

| BD : | Bore Diameter | 60 mm |

|---|---|---|

| D : | Diameter | 380 mm |

| BT : | Blade Thickness | 2.5 mm |

| SD : | Slot Depth | 14 mm |

| SW : | Slot Width | 3 mm |

| Steel Hardness | 34 HRC |

| Shapes |

|---|

Standard |  Sandwich |  Conical |

Pagode |  Mammouth |

| Dimensions | ||

|---|---|---|

| T. : | Thickness |  |

| S.T.H. : | Segment Total Height | |

| C.H. : | Concretion Height | |

| S.C. : | Side Clearance |

| Metallography | ||

|---|---|---|

|  | |

|  |

| Worn segments | New segments | ||

|---|---|---|---|

| Number of segments | 21 | 21 | |

| Analysis | Iron (Fe) | 36 % | 36 % |

| Cobalt (Co) | 54 % | 54 % | |

| Copper-Silver-Titanium (CuAgTi) | 10 % | 10 % |

| Porosity | ||

|---|---|---|

Opened |  Closed |

| Fractography | |||

|---|---|---|---|

Fractures around diamonds |  Fractures foot – matrix |  Diamond clusters |

| Welding |

|---|

The segments can be welded onto steel blades by conventional method (i.e. brazing alloys in strips, in wire, in paste, etc.) or by laser. A defficient welding can be at the origin of cutting defaults such as deviation cuts, loosed segments, etc. Therefore, it is important to verify the welding.

The welding analysis includes the control of :

- the parallelism of segments,

- the method used,

- the porosity,

- the presence of a foot,

- the composition of the brazing alloys.

The most important part of the cutting tool performance evaluation consists in an analysis of:

- the working surface

- the aspect of the diamonds

- the diamond concentration

- the quality and the grit sizes of the diamonds

Working Surface

The working surface analysis covers the general aspect of the surface (e.g. tails, protrusions, glazing surface, etc.), the diamonds distribution (e.g. presence of clusters), the diamond retention (e.g. number of pull-outs) and the ratio between:

- pull-outs

- polished crystals

- intact crystals

- crushed crystals

|  |

|  |

Diamond Aspects

All factors such as cutting parameters, manufacturing parameters, diamonds’ quality, diamonds’ sizes and the concentration have an impact on the diamonds’ behaviour and on the tools’ performances.

Indeed, during the cutting operations, the diamonds will be submitted to heavy constraints and will:

- stay intact

- clive or crush

- polish

- leave the matrix

|  |

Diamond crushed at the matrix level. There is no protrusion anymore. Diamond has lost its cutting properties. |  Diamond is crushed but still shows a protrusion. Diamond still keeps its cutting properties. |

Concentration

The concentration is measured according to the FEPA norm. By definition, the amount of diamonds present in a segment is calculated on a scale in which a concentration of 100 corresponds to 4.4 carats per cm³ or to 25% in volume.

FEPA

| Concentration | Carats/cm³ | % in volume |

|---|---|---|

| C10 | 0.4 | 3 |

| C20 | 0.9 | 5 |

| C25 | 1.1 | 6 |

| C30 | 1.3 | 8 |

| C35 | 1.5 | 9 |

| C40 | 1.8 | 10 |

| C50 | 2.2 | 13 |

| C60 | 2.6 | 15 |

| C75 | 3.3 | 19 |

| C100 | 4.4 | 25 |

Quality and Grit Sizes

The segments are dissolved into acid baths and the diamonds are cleaned.

Then, the same diamonds are sieved according to FEPA mesh sizes and each class is submitted to a battery of tests in order to estimate the quality of the diamonds.