DIAMOND ENCAPSULATION

REDUCES YOUR DIAMOND CONCENTRATION

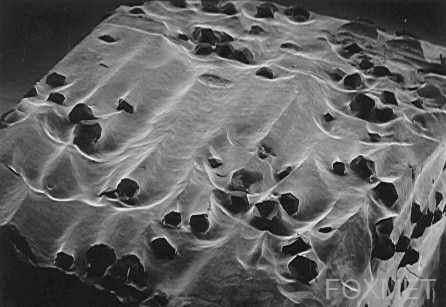

From our experience on the field and after analysis of worn diamond tools segments, we have noticed that the matrix erosion had a strong impact on the diamond retention and on the cutting performance of the sawing blades. As demonstrated by the pictures below, we realised that the erosion was particularly important in an area between 30 µm and 50 µm before and around the diamonds. When this erosion effect is too strong, it leads automatically to early diamonds pull-outs.

|  |

After several months of studies and trials, FOXMET S.A. has recently developed a new competitive process in order to tackle this problem. Indeed, through a very special granulation technique, FOXMET S.A. has succeeded to incorporate only one diamond per granule : the encapsulation.

|  |

The encapsulation of a diamond consists in the deposition of a metal layer around the diamond. Through FOXMET S.A. technology, it is now possible to control the thickness of a layer around the diamonds.

To this extent, it is also very important to understand that a layer which is too thin (ex.: 2 – 5 µm) will have nearly no impact on the diamond retention within the matrix.

Based on this concept, several sintering tests as well as cutting trials have been carried out and have demonstrated that encapsulated diamonds were better retained within the matrix than conventional manufacturing processes.

|  |

|

By using FOXMET S.A. encapsulated diamonds, the diamond tools manufacturers will drastically enhance the cutting performances of their sawing blades, reduce their manufacturing costs and, therefore, will improve their competitivity through :

- A better diamond distribution (reduction of clusters)

- A reduced diamond concentration

- A better diamond retention

- A better protrusion of the diamonds

- An improved evacuation of sludges

- A reduction of the matrix costs

This new concept can be successfully applied to disc sawing, gang saw blades, diamond wires and drills.