Diamond paste for infiltration

Foxmet's stabilized pastes

Simplify your manufacturing process and improve your tool’s cutting performances

Stabilized Paste

Perfect Distribution

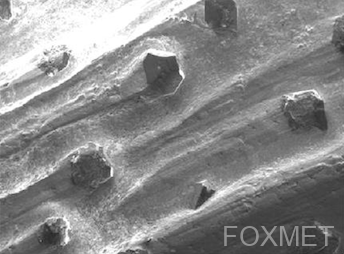

25/35 Mesh Presintered Encapsulated Diamonds Pasted with Fused/Cast WC

Main Advantages

– No more segragation between coarse and fine particles.

– Easy to pack in the moulds.

– Ideal for complex tool’s shapes.

– Long shelf life and remain Malleable.

– Improved diamond distribution. No more clusters.

– Improved cutting performances.

Infiltration Attempt of a Bit with Presintered Encapsulated Diamon Containing WC/CuMn 70/30 and Pasted with Fused/Cast WC Infiltration done under AMBIENT Atmosphere, after sand blasting

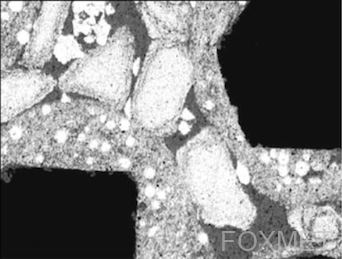

Random & Uneven Diamond’s Distribution

Improved Diamond’s Distribution

Reinforced with Spherical Cast/Fused WC

And Pasted with Coarse Cast/Fused WC

Molding procedure for infiltrated petroleum drill bits with encapsulated and pasted diamonds

Fix Water Pipes & Cutting Structure / PCD

Start to pour the cutting edges with the paste and then pack/press the paste

Pour the whole cutting head with paste, pack/press the paste to reduce voids and fix the drill bit’s bottom part

After infiltration, check porosities on whole drill bit’s surfaces