tungsten

| Analysis | Elements | Specifications | Typical |

|---|---|---|---|

| Tungsten (W) | 99.9 % min.* | Balance | |

| Aluminium (Al) | 25 ppm max. | < 10 ppm | |

| Calcium (Ca) | 20 ppm max. | < 10 ppm | |

| Cobalt (Co) | 100 ppm max. | 20 ppm | |

| Chromium (Cr) | 75 ppm max. | < 20 ppm | |

| Copper (Cu) | 10 ppm max. | 1 ppm | |

| Iron (Fe) | 100 ppm max. | 20 ppm | |

| Molybdenum (Mo) | 200 ppm max. | 50 ppm | |

| Natrium (Na) | 15 ppm max. | 10 ppm | |

| Nickel (Ni) | 15 ppm max. | 10 ppm | |

| Silicon (Si) | 30 ppm max. | 15 ppm | |

| * Oxygen (O) content excluded. The oxygen level may vary between 0.02 % and 0.40%, depending on the particles sizes. |

| Particle Size | FSSS | 0.5 – 0.9 µm +/- 0.1 µm | |

|---|---|---|---|

| 1.0 – 1.3 µm +/- 0.2 µm | |||

| 1.4 – 1.7 µm +/- 0.2 µm | |||

| 1.8 – 2.7 µm +/- 0.3 µm | |||

| 2.8 – 3.9 µm +/- 0.3 µm | |||

| 4.0 – 6.0 µm +/- 0.3 µm | |||

| Other particle sizes are available upon request. |

| Packaging | Drums or Pails of 50 kg net | ||

|---|---|---|---|

| Other packaging upon request |

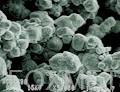

WC 4 µm

WC 4 µm

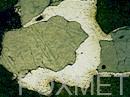

Secondary carbides

formation in cobalt

based matrix

(Picture Dr. A.Fels)

Secondary carbides

formation in cobalt

based matrix

(Picture Dr. A.Fels)

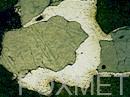

Sintered WC with

diamonds in cobalt

based matrix

(Picture Dr. A.Fels)

Sintered WC with

diamonds in cobalt

based matrix

(Picture Dr. A.Fels)

| Analysis | Elements | Specifications | Typical |

|---|---|---|---|

| Tungsten (W) | 99.7 % min.* | Balance | |

| Carbon (C) Total | 6.13 % +/- 0.05 % | 6.12 % | |

| Carbon (C) Free | 0.06 % +/- 0.02 % | 0.02 % | |

| Aluminium (Al) | 25 ppm max. | < 20 ppm | |

| Calcium (Ca) | 50 ppm max. | 16 ppm | |

| Cobalt (Co) | 100 ppm max. | 20 ppm | |

| Chromium (Cr) | 75 ppm max. | 16 ppm | |

| Copper (Cu) | 15 ppm max. | < 5 ppm | |

| Iron (Fe) | 250 ppm max. | 70 ppm | |

| Molybdenum (Mo) | 250 ppm max. | 24 ppm | |

| Natrium (Na) | 20 ppm max. | < 5 ppm | |

| Nickel (Ni) | 50 ppm max. | 5 ppm | |

| Silicon (Si) | 50 ppm max. | 20 ppm | |

| * Oxygen (O) content excluded. The oxygen level may vary between 0.02 % and 0.20%, depending on the particles sizes |

| Particle Size | FSSS | 0.9 – 1.1 µm +/- 0.1 µm | |

|---|---|---|---|

| 1.2 – 1.7 µm +/- 0.2 µm | |||

| 1.8 – 3.2 µm +/- 0.2 µm | |||

| 3.3 – 6.3 µm +/- 0.3 µm | |||

| Other particle sizes are available upon request. |

| Packaging | Drums or Pails of 50 kg net | ||

|---|---|---|---|

| Other packaging upon request |

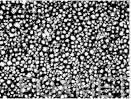

Pre-alloyed Powder

Pre-alloyed Powder

Sintered Structure

Sintered Structure

| Analysis | Elements | Specifications |

|---|---|---|

| Tungsten (W) | Balance | |

| Cobalt (Co) | 12 or 15 or 20 % |

| Particle Size | 0 – 100 µm | |

|---|---|---|

| 0 – 200 µm | ||

| 0 – 300 µm | ||

| Other grain sizes upon request. |

| Hardness | HV10 (Iso 3878) | 1250 |

|---|

| Coercity | Hc | 165 oested |

|---|

| Analysis | Elements | Specifications | ||||||

|---|---|---|---|---|---|---|---|---|

|

|

|||||||

|

|

|||||||

| Other mixture grades available upon request. |

| Packaging | Drums or Pails of 50 kg net | |

|---|---|---|

| Other packaging upon request |

Fused tungsten carbide powders are specially treated, controled and screened. Each powder is formulated to achieve an

optimum value in hardness, abrasion and erosion as well as

impact resistance. In addition and due to excellent

wetting properties, fused tungsten carbide powders allow to achieve superior infiltration absorption values.

These powders are used for manufacturing diamond tools such as: saw blades, core bits, drill bits and other

infiltrated components. Among the main industrial applications, fused tungsten carbide powders are used for cutting

abrasives materials such as asphalt and concrete. Another famous application being the geological surveys and,

particularly, the drilling oil-wells.

| Analysis | Elements | Specifications | Typical |

|---|---|---|---|

| Tungsten (W) | Balance | Balance | |

| Carbon (C) Total | 3.90 – 4.20 % | 3.98 % | |

| Carbon (C) Free | 0.10 % max. | 0.08 % | |

| Iron (Fe) | 0.40 % max. | 0.22 % | |

| Oxygen (O) | 0.10 % max. | < 0.06 % |

| Particle Size | – 200 Mesh | 0 – 75 µm | |

|---|---|---|---|

| – 150 + 200 Mesh | 75 – 106 µm | ||

| – 100 + 150 Mesh | 106 – 150 µm | ||

| Other grain sizes upon request. |

| Packaging | Drums or Pails of 25 and 50 kg | ||

|---|---|---|---|

| Other packaging upon request |