Mining Core Bits

New Patended concepts

In order to improve core bits tool life and their drilling efficiency, our new product lines involved the use of diamond aggregates comprising both peripherical diamonds and peripherical fused/cast tungsten carbides.

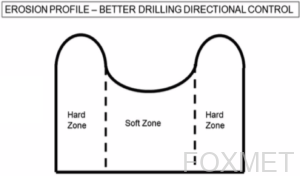

General erosion profile for better directional drilling control

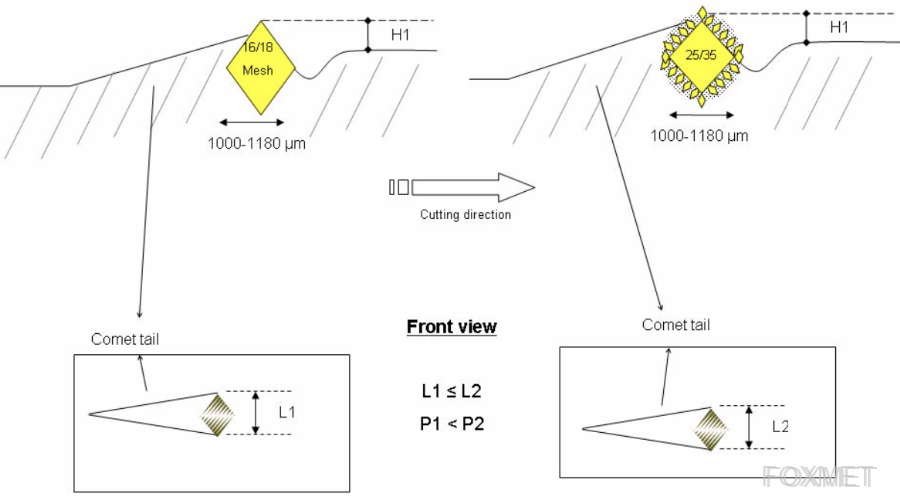

Transversal Width Cut

Reduced Diamonds' Protusion In mixtures

In conventional mixture, finer diamond grit’s comet tails hinder and/or reduce coarser grit’s protusion. Finer grits play the role of fused/casted tungsten carbides. Finer grits harden the main matrix leading, consenquently, to reduced cutting performance of the diamond tool.

mono versus multi protusions

Mono-protusion

Multi-protusions

Side view

L = Tail’s Width

P = Number of Protusions

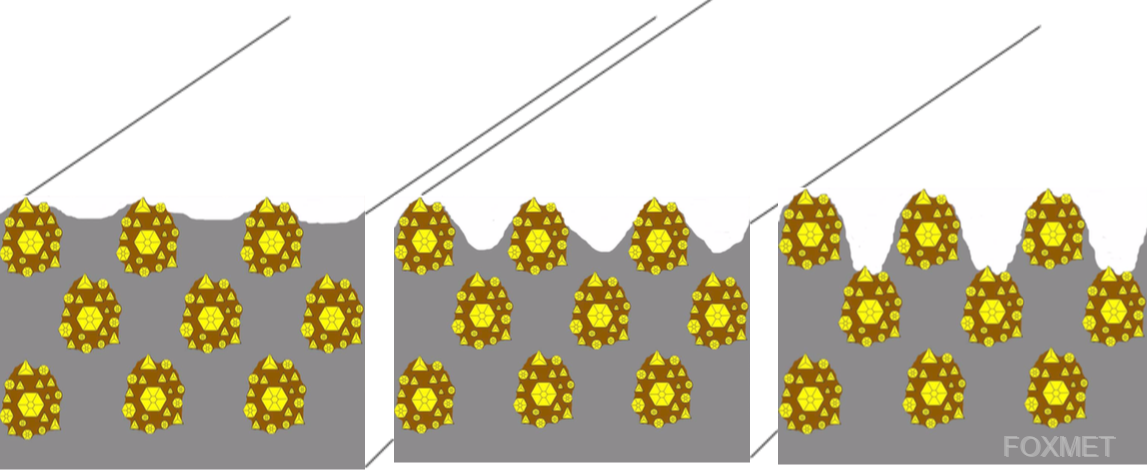

Diamonds aggregates increased protrusion

At constant diamond’s concentration, aggregated diamond’s protusions are concentrated in deliminated areas of diamond tool’s inserts/segments. This, in turn, allows easier matrix erosion around & before those deliminated areas.

Also, if H3=H1, then S3<(S1+S1-2+S1-3+S1-4+S2)

Aggregates erosion progression - front view

1° Matrix erosion starts.

Aggregates occur on surface

2° Weight Loss increases.

Channels formation on surface

3° Weight Loss stops.

Shearing-Off cutting mode takes place

Aggregates erosion progression - profile view

1° Aggregates occur on working surface

2° Front aggregates protrude

3° Back aggregates protrude

Front aggregates erode

4° First layer aggregates erode

Second layer aggregates occur

5° Front aggregates disapear

Second layer aggregates protrude

6° First layer aggregates disapear

New cutting cycle with 2ns layer

Concepts 1, 2 & 6 - Fused WC Aggregates - Balmoral FG (granite class 5)

Concepts 1, 2 & 6 - Fused WC Aggregates - Low Speed SANDSTONE

Concepts 1, 2 & 6 - Fused WC Aggregates - High Speed SANDSTONE